Use of long poles for aerial / Starlink installations

Subject list :

- Why use a longer pole ?

- Tests of aerial reception with longer poles

- How do I install an aerial on a long pole ?

- Sleeving a 1.5" pole into a scaffold pole, also suitable for Starlink

- "Double poles" : is it a bodge ?

- How do I transport a long pole ?

Use Of Longer Poles

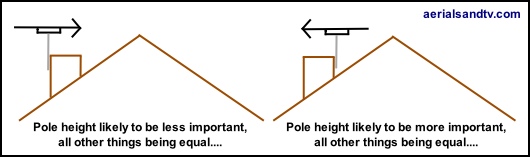

Theoretically the higher an aerial is mounted the more signal it will receive. It is certainly the case that if any additional height is used to give adequate clearance (preferably by at least 3ft) to an obstruction in the path to the transmitter (e.g. a roof) the additional wind loading and larger bracket(s) required are very worthwhile. However in most cases (assuming the aerial is mounted at “normal” installation height, say 25ft from the ground) unless there is an obvious barrier to the transmission path I have my doubts about just how much extra signal you would get from (say) using a 10ft pole rather than a 6ft. Remember we’re talking the difference in the total aerial height, e.g. from 25ft to 29ft. Obviously if you live in a dip and your reception path is only just clearing the hillside, or indeed is through it, then any extra height may be significant, but generally speaking I wouldn’t expect miracles. Quite apart from anything else reception sites vary from sea level to 1000ft (or more) so how is four foot going to make that much difference ! Having said all of the above, particularly if the aerial is mounted relatively low to the ground (e.g. on a bungalow), and you’ve tried everything else, then a longer pole is always worth a punt !

In April 2008 we did some aerial height experiments to see on just how much extra signal one gets from an aerial 3ft 3in higher (the extra height from a 10 ft pole over a 6ft) and these more or less backed up the advice previously given above. Also see "Anatomy of an awkward install".

On a related point if you are suffering from signal problems then moving the aerial laterally may well be more effective than using a higher pole.

How do I install an aerial if it’s on a long pole ?

Actually, this really isn’t such a stupid question, read on……

First, back to basics. When an installer puts up an aerial it’s almost always pre-installed on the end of the pole (c/w the cable taped down the side of the pole) then the pole is bolted to the bracket. The aerial is almost never installed on the end of the pole whilst the pole is in situ, for obvious reasons. Now, fitting the pole to the bracket with the aerial already installed on the top of it is all very well if the pole is relatively short (up to 6ft) but if the pole is a long one (10ft plus) that’s a rather different ball game, particularly if the aerial is a large one. Think about it, you’re holding the pole at the bottom with the aerial at the top ( = large leverage effect) and then trying to slide it into the (loosely fitted) V bolts on the bracket, all whilst you’re perched at the very top of the ladder. Remember, there isn’t usually room to get the ladder much higher than the bracket because the bracket is usually near the top of the wall (in order to gain maximum height) !

There are two approaches. The first involves sliding the pole (c/w pre installed aerial) into just the bottom (loosely fitted) V bolt, tightening the latter then helps stabilise the pole before you install the top V bolt. This can be worthwhile because if it’s a long pole the bottom V bolt will be up to 18 inches or more below the top one, thus you can hold the pole a bit higher up and/or you’ll be further down the ladder. The alternative approach involves pre installing the aerial as usual but not taping the cable all the way down it. Thus you can clamp the pole to the bracket nearer the top of the pole and gradually push up the aerial / pole combination (by temporarily slackening off the V bolts) taping the cable to the pole as it emerges from the top V bolt . This method is more problematic if you’re using saddles because the saddles bite into the pole, even on loosened V bolts, and the pole doesn’t slide as smoothly through the V bolts. This does at least prove that saddles do work ! !

Very important ! It should go without saying that fitting an aerial in high winds is a big no no. In fact, if it’s a large aerial on a long pole, I’d say it’s a bad idea to try and fit it if there’s any significant wind at all !

And use your ladder safely……

Sleeving a 1.5" pole into a scaffold pole (also suitable for a Starlink pole)

As of Sept 23 we sell a 2" to 1.5" pole coupler which achieves more or less the same result rather more easily, though you do have the 1.3Kg of the coupler added to the pole's weight, and relatively high up it.

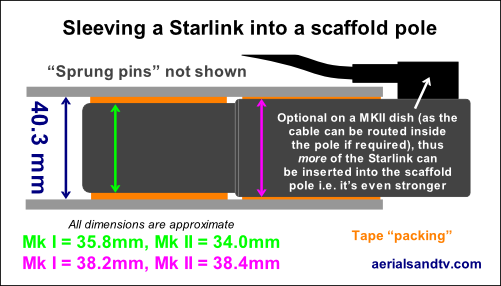

The article below was originally written about how to extend a scaffold pole by sleeving a 1.5" pole into it, but it is just as relevant for installing a Starlink because they also have a 1.5" diameter pole, see adjacent diagram. Bear in mind the join does not have to be as rugged as that described below because the distance from it to "the load" (a Starlink) is under a foot, not 8ft as it would be in the case of an aerial on the end of an extended scaffold pole. It will certainly be far more durable, and elegant, than the genuine Starlink pole adapter.....

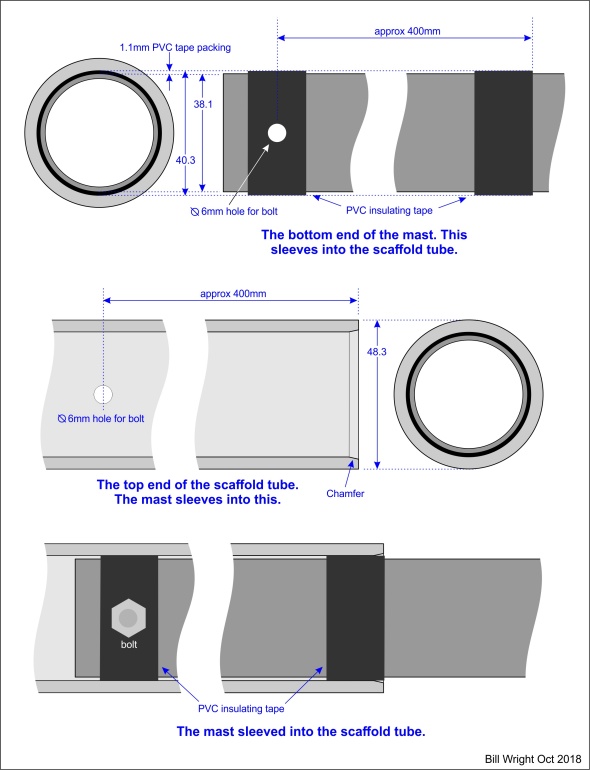

This method can give you an aerial mast with a height of about 18ft using a scaffold pole and an 10ft x 1½" pole. The weight and strength are low down. This is far stronger and more stable than a 2” aerial mast of the same length (it's also lighter and cheaper than a 20ft scaffold pole and can avoids extra carriage charge for poles over 10ft !). There isn’t much clearance between the inside diameter of the scaffold tube and the outside diameter of the aerial mast. The small gap must be tightly filled however or the installation will rattle. After a lot of experimentation we found a simple solution: a few turns of good quality PVC insulating tape. The tape should be in two locations: right at the top of the scaffold tube (corresponds to about 400mm from the bottom of the aerial mast) and right at the bottom of the top section of 8ft x 1½" pole (corresponds to about 400mm from the top of the scaffold tube. Wrap the tape around the aerial mast, making a slightly tapered shape that will slide into the scaffold tube. Keep adding one turn at a time until the tape at the bottom end of the aerial mast is a snug fit [for a Starlink (this is not that necessary for the MkII) you will need to wind on more tape at the 35.8mm end, we suggest using self amalgamating tape or even just decent quality insulation tape]. For the tape at the top end of the aerial mast do the same but go slightly beyond a snug fit. Cut a slight chamfer on the inside surface of the scaffold tube to lead the tape in, this can be cut easily with a sharp knife. Insert the aerial mast into the scaffold tube (you can use cable pulling fluid to lubricate if you like) and ram it home [do not "ram" in a Starlink, obviously. Just push it in as hard as you can, possibly using a lubricant, it'll be fine] so the top tape is really tight and compressed. Ram the assembly against a wall or tree or whatever. The two tubes should now be firmly locked together. Drill a 6mm hole through both poles at the point where the lower tape is [when drilling through a Starlink MkII stub pole care should be exercised that you do not drill through the Ethernet cable which is inside it on the Mk2 version, alternatively (and more safely.....) sleeve a section of 1.5" pole into the top of the scaffold pole then use a 1.5" pole coupler to clamp the Starlink on to that. Check this ! > Either way you may need to offset the through bolt to ensure enough room to get the Starlink Ethernet plug past.]. Insert a 6mm bolt or machine screw, tighten and apply Loctite or use a Nyloc nut. Don’t overtighten, the bolt will snap before the tube deforms. Don’t drill through where the mast goes into the scaffold tube because that would weaken the main stress point. I like to wrap self-amalgamating tape over the top edge of the scaffold tube running it onto the aerial mast, just in case frost gets in. If you would like a professional installer for this sort of job and are in the Sth Yorks / Nth Midlands area try Don Valley Aerials (07930 347632).

(Bill Wright, October 2018)

1.2m Scaffold pole

2.0m Scaffold pole

2.4m / 3.6m / 6.0m poles

“Double pole” installs : is this a bodge ? Do they work ?

This is rare, I can’t remember when I last saw one of these.

Is this install a bodge ? We’ll ignore the fact the installer has used painted K brackets (though he has at least used two "K"s) but we can’t disregard the aerial / pole combination he’s used. One assumes he’s used a “double pole” because the aerial was swaying around alarmingly in the wind, but the fact he’s used an aerial with a very high windloading must have contributed to that just as much as the pole's strength or lack of it. That aerial, which is on Emley Moor by the way, looks like a SAC Mux Magician (or a similar type, see test of this aerial) and they have a wind loading of about 150N at 80mph. A Yagi 18B on Emley would actually have more gain but also half the windloading (around 75N at 80mph) ! It’s actually better made as well but that’s not entirely relevant here.

Onto the actual “double pole”, I think it’s fair to say a scaffold pole would have been just as strong, looked better and probably have been more reliable long term, but what I think has happened here is the installer has put up a pole about 15ft long then become concerned at the amount of movement in when the wind blows. We’ll give him the benefit of the doubt that he used a heavy duty 14G/2.0mm wall thickness pole, though he may have used a thinner one, either through lack of knowledge or by design because he’s a tight arse (if he used a 16G/1.6mm pole he is a bodger). So, he thought “what can I do here ? I know what about using a second pole (10ft this time) to support the first by clamping them together with three 2x2 clamps !” Personally I think he’s put the clamps in the wrong place, I’d have thought one just below the bottom bracket, one just below the top bracket, and the third at the top of the “support pole” would have been more logical.

Anyway, we tested two double pole assemblies, one with the support pole on top, and one with it on the side where the clamps would have been working in a different mode. We used 10ft x 1.5in poles and 5ft x 1.5in support poles. The assembly with the secondary pole on top was just under 60% stronger, the one with it at the side was around 100% stronger. I think the difference was down to how the main pole was clamped as it left the top 2x2 clamp and thus affected the stress pattern on the main pole at that critical point.

Having said all the above, it is another question entirely how this double pole assembly will last when subject to repeated wind movement over the years…..

How do I transport a long pole ?

Ideally use a truck, but not many of us have one of those..... However, ladder bars* are a pretty good (and obvious) alternative apart from the fact that is not immediately apparent how to lash a pole to a pair of ladder bars. There is, thank Gawd, a very effective, cheap and simple to use method which anyone can use. And the answer is........ insulation tape ! Yes it really is. Place the pole across the bars then wind the insulation tape (figure of 8 like) round them both, but, critically, stretch the tape as you do so, though you have to make sure the tape isn't too cold. Once you have few thicknesses of tape the pole will not move, guaranteed. Once you get to where you need to be just cut it off. Simple. [link]

* Don't get me onto the subject of ladder bars, or more precisely, modern ladder bars..... Oh all right then, there are many retrograde developments in car technology and modern ladder bars are a perfect example of it. Do you remember when you could get a perfectly serviceable set of ladder bars from a decent car spares shop for about £20 and, even more importantly, they'd fit any car? These days loads of cars need specialised bars which will only fit that car and cost ridiculous amounts of money, even non genuine types often cost between £50 and £100. OK so they might look nicer, but most people don't leave them on permanently anyway, so to me it's a backward step in nearly every way, like much to do with over complex cars which are becoming increasingly unfixable. They do 10% more MPG but when the overly complex engines go wrong it costs £100s (or even £1000s) to put right. It's bollox, that's what it is.